2.1 Umbrella industry organisation

Vereniging ION was created from a merger of several industry organisations active in the surface finishing industry. The main reason behind the merger was the fragmented manner of response to (new) regulations and legislation up to that point. Additionally, the various associations had mainly been focussed on short-term interests for the industry itself, leading to polarisation with competent authority.

The founding of Vereniging ION shifted the focus from the issue of regulation and legislation to ‘Dutch Ltd interests’. After all, the industry also depends on quality environmental and work safety regulations and legislation. Additionally, greater emphasis was placed on the continued development of the growing economy of Dutch Ltd. businesses. A strong manufacturing industry is important to our economy, and a state-of-the-art surface finishing industry is a crucial supporting agent of a strong manufacturing industry. After all, virtually all current technological innovations are surface finishing technology related.

Vereniging ION presents itself as an industry association 4.0. Its structure is defined in a free-to-download e-book: https://bit.ly/31nwBFa.

2.2 Strong sector

The surface finishing industry represents a powerful and versatile sector where, in addition to technology, (inter)national regulations and legislation play a directive and often restrictive role. This forces the industry to remain innovative in its search for new possibilities. Vereniging ION functions as a linchpin which unifies different parties, encourages innovations, and participates proactively in the formation of new regulations and legislation. For more information, visit www.vereniging-ion.nl.

One of Vereniging ION’s priorities is: sitting down with Brussels and The Hague. Many surface finishing businesses deal with both health & safety and environment-related laws, directives, and rules. For example, the European REACH directive imposes demands on the use of specific substances, used in decades-old products or methods, that can often not easily be replaced with alternatives. In these cases, rushing the prohibition of the use of certain substances may even lead to loss of quality or economic damages. Vereniging ION maintains a close relationship with policy makers in both Brussels and The Hague, holds consultations with regulatory committees and, as a member of various (European) working groups and umbrella organisation, is a shaping force behind the (future) legal emphasises rational planning and implementation where, from the perspective of work safety, both technical and economic possibilities as well as member interests are explicitly taken into account.

The slogan: ‘Replace what you can, authorise what you have to – but do it safely!’ has been copied by many agencies. It is a policy that leads to results. Former industry organisations were frequently avoided by the competent authorities based on the principle that ‘they cannot object to what they do now know about’. Vereniging ION, however, encourages a fair and open dialogue as a constructive, proactive conversational partner, who has frequently been taking the initiative.

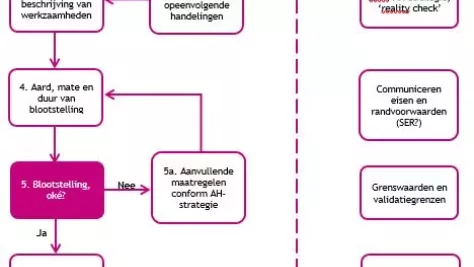

Since 2015, the flowchart for safe working methods used by Inspectorate SZW (Inspectorate for Social Affairs and Employment) has been as follows:

Safe working methods process description|Role of Inspectorate SZW

| 1. Industry agency taking the lead | 1./2. Identify and encourage possibilities | |

| 2. Identification of activities to be addressed | 2a. Observe state of knowledge/AH-strategy | |

| 3. Standard description of activities | 3a. Additional exposure, subsequent activities | SaW, AH strategy, reality check |

| 4. Nature, extent, and duration of exposure | Communicate demands and prerequisites (SER?) | |

| 5. Exposure, okay? | 5a. Supplemental measures in compliance with AH-strategy | Benchmark values and validation thresholds |

| 6. Assess for additional exposure | Description of reality, demarcation | |

| 7. Document safe working methods incl. process | 7a. Instructions for employers and employees | 7./8. Inclusion in health and safety assessment, safe working methods, or good practice catalogue |

| 8. Safe working method as basis for supervision |

The relationship with the competent authority has also improved. After all, we all really want the same thing: making a quality product in a safe and healthy manner at a price that is in line with market practice.

An important aspect of the collaboration between the industry and the Government and competent authority relates to providing information and sharing knowledge. Although Vereniging ION is part of the EU Transparency register, the acts of providing information and lobbying must be regarded as strictly separate. For example, the latter is involved:

- Meeting ministries, DGs (Directorate-General), commissions and consultation forums in The Hague and Brussels.

- Discussions with members of the States General and European Parliament.

- Intensive contact with ECHA (European Chemical Agency) and the European Commission’s advisory body.

- Access to the Permanent Representation of the Netherlands in Brussels.

- Intensive contact with Inspectorate SZW and, to a lesser extent, Inspectorate L&M.

- Business visits with inspectors and decision-makers.

- Actively forging connections between European research institutes and industry members.

- Participate in meetings of European umbrella organisations like CETS (European Association Surface Engineering), Eurometeaux and Orgalime (Task Force Substances).

- Remain committed to the CTACSub agenda (Chromium-6 consortium companies).

- Member of ‘Veiligheid Voorop’ (Safety First).

- Contact with entrepreneurial organisations ONL, VNO/NCW and MKB-Nederland.

- Consulting with materials institutes like the Nickel Institute and Cobalt Development Institute.

- Contact with universities and research institutes like Delft University of Technology and Radboud University MC.

- Contact with adjoining industry organisation with similar vision or position, like VNMI, FME or Koninklijke Metaalunie.

- Completing questionnaires at the Dutch and European levels.

- (Co-)organising studies and questionnaires.

- (Co-)organising workshops, conferences, and events.

- Organising the ‘Week of Surface Technology’.

- Organising the ‘ION Dag voor de Ondernemer’ (ION Entrepreneur Day).

- Co-organising ‘Nationale Stoffendag’ (National Substance Day).

- Supporting and facilitating the ION Borghardt Award for industry innovations.

- Visiting relevant informative days and conferences.

- (Co-)developing informational materials for the website, the OT (Surface Technology) trade journal, and third-party media. Several interesting examples by Inspectorate SZW are:

- https://bit.ly/2ttQNc0

- https://bit.ly/39alp1C

- YouTube vid part 1, the applicator: https://bit.ly/2S0VhjG

- YouTube vid part 2, the supplier: https://bit.ly/2Uqzdko

- YouTube vid part 3, the industry association: https://bit.ly/2vRgUKV